Durability and Impact Resistance

EIFS with Drainage are designed to be durable and long-lasting, which translates to low maintenance. Most EIFS with Drainage systems are specially formulated with a 100% acrylic binder, which gives finishes superior resistance to fading, chalking, and yellowing. As a result, the systems tend to maintain their original appearance over time.

Highly impact-resistant EIFS with Drainage are easily achievable using standard application practices and products that are effective and economical. Designing and specifying impact resistance for EIFS with Drainage is relatively simple, but in the cost-competitive construction environment, high-impact systems and features are sometimes bypassed under the guise of value engineering. This practice must be avoided, especially in geographical regions (typically coastal) where high impact resistance is mandated by code. EIFS manufacturers have developed and tested systems to meet specific requirements that address windborne debris and cyclic wind pressure. The designer simply needs to consider these requirements and select from properly tested and approved systems.

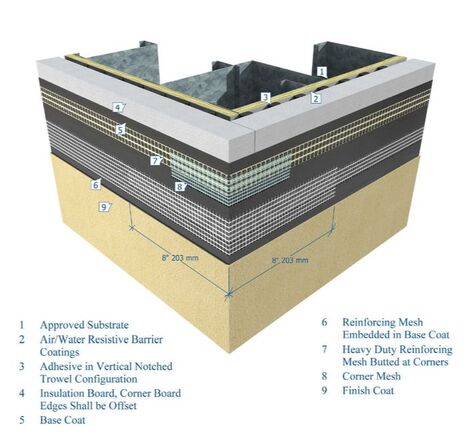

One of the primary “tools” that provides impact resistance in EIFS with Drainage is the type and weight of the glass-fiber reinforcing mesh. The mesh is available in different weights and is embedded in the base coat, which has been applied to the insulation. Higher impact resistance is an important consideration for areas such as entrances, columns, and other regions subject to surface impacts. ASTM E2486, Standard Test Method for Impact Resistance of Class PB and PI Exterior Insulation and Finish Systems (EIFS), establishes four impact-resistance classifications for EIFS — Standard, Medium, High, and Ultra High — which are achieved through increased weights of reinforcing mesh and/or multiple layers of reinforcing mesh. For areas where impact is anticipated, such as wall areas within 8 feet of grade and projects in high-wind regions, specifying a high-impact or ultra-high-impact mesh assembly should be considered.

Specific impact testing requirements for exterior walls were developed after Hurricane Andrew hit South Florida in 1992. The benchmark for impact resistance due to wind events such as hurricanes are small/large missile impact tests, which are often required in high velocity hurricane zones (HVHZ) such as Dade County and other coastal locations. Exterior wall assemblies incorporating EIFS with Drainage can be designed to comply with small and large missile impact test requirements through use of heavier weight and or multiple layers of reinforcing mesh. The substrate may also influence impact performance and benefit from reinforcing mesh embedded in base coat particularly for more dynamic tests such as the large missile impact test.

Highly impact-resistant EIFS with Drainage are easily achievable using standard application practices and products that are effective and economical. Designing and specifying impact resistance for EIFS with Drainage is relatively simple, but in the cost-competitive construction environment, high-impact systems and features are sometimes bypassed under the guise of value engineering. This practice must be avoided, especially in geographical regions (typically coastal) where high impact resistance is mandated by code. EIFS manufacturers have developed and tested systems to meet specific requirements that address windborne debris and cyclic wind pressure. The designer simply needs to consider these requirements and select from properly tested and approved systems.

One of the primary “tools” that provides impact resistance in EIFS with Drainage is the type and weight of the glass-fiber reinforcing mesh. The mesh is available in different weights and is embedded in the base coat, which has been applied to the insulation. Higher impact resistance is an important consideration for areas such as entrances, columns, and other regions subject to surface impacts. ASTM E2486, Standard Test Method for Impact Resistance of Class PB and PI Exterior Insulation and Finish Systems (EIFS), establishes four impact-resistance classifications for EIFS — Standard, Medium, High, and Ultra High — which are achieved through increased weights of reinforcing mesh and/or multiple layers of reinforcing mesh. For areas where impact is anticipated, such as wall areas within 8 feet of grade and projects in high-wind regions, specifying a high-impact or ultra-high-impact mesh assembly should be considered.

Specific impact testing requirements for exterior walls were developed after Hurricane Andrew hit South Florida in 1992. The benchmark for impact resistance due to wind events such as hurricanes are small/large missile impact tests, which are often required in high velocity hurricane zones (HVHZ) such as Dade County and other coastal locations. Exterior wall assemblies incorporating EIFS with Drainage can be designed to comply with small and large missile impact test requirements through use of heavier weight and or multiple layers of reinforcing mesh. The substrate may also influence impact performance and benefit from reinforcing mesh embedded in base coat particularly for more dynamic tests such as the large missile impact test.